Photos Richard has uploaded

Here are all of the photos that Richard has uploaded.

The first of the support columns go vertical on Movie World's hypercoaster.

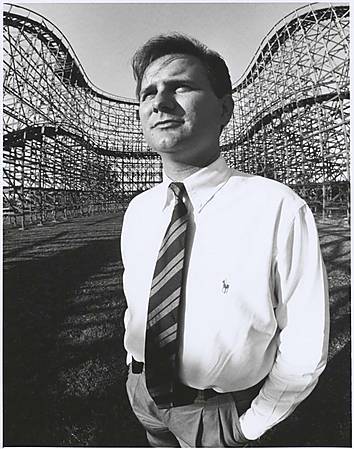

Then manager Tim Fisher looks over The Bush Beast. Fisher would later return to his native USA to oversee Paramount's theme park operations before returning to Australia as CEO of Village Roadshow Theme Parks.

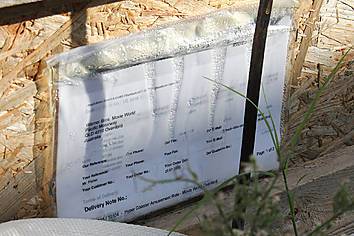

A packaging slip on one of the Mack Rides crates confirms the style of ride and also the date that the ride was officially ordered: 28 July 2015. Mr Fisher is Tim Fisher, CEO of Village Roadshow Theme Parks.

Batwing Spaceshot temporarily out of order with seat covers in place.

Wild West Falls splashing down.

The skyline at Warner Bros. Movie World will be radically different in a few short months.

Foundation templates that were never used.

The footings at the construction site have been cleaned up ahead of vertical construction.

The rainfall has made the site a bit damp, but nothing that a few days of clear weather won't fix.

Only small puddles remain from the deluge experienced this week.

The removed palm trees lay on the ground awaiting replanting.

Several palm trees were removed in the process.

This section of the car park wasn't fenced off, indicating it could join the cutaway for a temporary entrance to Movie World during construction.

A section of the garden bed and gutter has been cut away, presumably to build a temporary road during construction.

Track is delivered in open-top containers. Each section is lifted out with a crane and placed into the staging area.

This slow and steady process of just getting the parts ready gives an indication of the sheer amount of planning, logistics and work goes into building a roller coaster of this scale.

And there's certainly no shortage of space for these pieces of track.

All up there are currently ten pieces of track on site. Only about 100-200 to go...

Anytime you see these I-beam protrusions (H-beams in this photo), you're looking at the base of a support column.

Here you can get a good idea of the different support joins. The circular plates with 12 small holes join end-to-end to form longer columns. The large octagonal plate (and the square plate behind it to the left) sit on the concrete footings, while the smaller square plate to the right is what joins onto the track.